Integrating a Swiss type CNC lathe into an existing production line can significantly enhance precision, efficiency, and overall output. These machines are designed to produce small, intricate components with high accuracy, making them ideal for industries such as medical, aerospace, and electronics. However, successful integration requires careful planning, proper workflow design, and attention to compatibility with existing equipment.

Assess Production Requirements

Before adding a Swiss type CNC lathe to your production line, it is essential to assess your manufacturing needs. Consider the types of components being produced, required tolerances, production volumes, and material types. Identifying the specific demands of your operation will help determine the ideal lathe model, tooling configuration, and automation features necessary for seamless integration.

Evaluate Workflow and Layout

The physical placement of the lathe within the production line is critical. Evaluate the existing workflow to ensure that materials can move efficiently between stations without bottlenecks. Consider factors such as space availability, access for operators, material handling systems, and proximity to other machines. Proper layout planning reduces handling time, minimizes delays, and ensures that the lathe can operate at its full potential without disrupting the overall production flow.

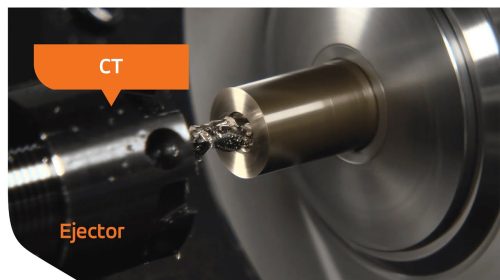

Ensure Compatibility and Automation

Swiss type CNC lathes are designed to work with advanced automation systems, including bar feeders, tool changers, and conveyors. When integrating into an existing line, compatibility with these systems is crucial for smooth operation. For manufacturers looking to optimize production, a swiss type cnc lathe offers advanced automation options and flexible interfacing, making it easier to synchronize with upstream and downstream equipment. Ensuring that control systems, software, and communication protocols are compatible with your current setup reduces downtime and enhances operational efficiency.

Train Operators and Staff

Integrating a new machine requires training for operators and support staff. Operators should be familiar with CNC programming, machine setup, tool changes, and maintenance routines. Staff responsible for material handling, quality control, and workflow monitoring should also understand how the lathe fits into the overall production process. Well-trained personnel reduce errors, improve throughput, and ensure that the lathe contributes effectively to the production line.

Implement Quality Control Measures

Precision machining requires robust quality control procedures. When adding a Swiss type CNC lathe to an existing line, it is important to integrate inspection and monitoring systems. Real-time measurement, in-process inspection, and feedback loops help maintain tolerances and identify deviations early. By incorporating these quality control measures, manufacturers can ensure that parts meet specifications consistently and reduce the risk of defects affecting downstream processes.

Optimize Tooling and Maintenance

To maximize efficiency, plan for proper tooling and maintenance support. Stocking essential tools, inserts, and consumables near the lathe minimizes downtime during tool changes. Scheduled preventive maintenance and routine inspections ensure the machine remains in optimal condition and reduces unexpected breakdowns that could disrupt the production line. Proper maintenance planning also supports long-term accuracy and reliability.

Adjust Material Handling and Logistics

Material handling systems may need to be updated to accommodate the Swiss type CNC lathe. This includes conveyors, robotic arms, storage racks, and loading/unloading stations. Efficient logistics reduce manual handling, minimize errors, and ensure a continuous flow of materials to and from the lathe. Planning for ergonomic and automated material handling improves both safety and productivity.

Monitor Performance and Optimize Workflow

After integration, monitoring the lathe’s performance and its impact on the overall production line is essential. Track metrics such as cycle time, yield, downtime, and throughput. Analyze data to identify bottlenecks, optimize tool paths, adjust feed rates, and improve overall workflow. Continuous monitoring and optimization ensure that the Swiss type CNC lathe contributes to a more efficient and profitable manufacturing process.

Conclusion

Integrating a Swiss type CNC lathe into an existing production line requires careful planning, operator training, workflow analysis, and quality control measures. By ensuring compatibility with automation systems, optimizing material handling, and maintaining the machine regularly, manufacturers can enhance precision, reduce cycle times, and improve overall productivity. Proper integration transforms the lathe into a reliable and efficient asset that strengthens the entire production process and supports long-term operational success.